Tank cleaning services must be tailored to your facility needs. At TEAM Group, we wouldn’t have it any other way. With an array of Tank Cleaning Machines (TCMs) and 3D industrial cleaning technologies advancing quickly, what are the requirements and options for tank cleaning services today? Read on to find out everything you need to know about the important and necessary services related to facility and field expert tank cleaning.

TEAM samples material, cleans and removes sludge from various industrial tanks. We have 40 years of comprehensive experience and tank cleaning knowledge for specialized environments. Our crews tailor many site-specific work procedures and safety plans based on accessibility points and downtime to the site requirements.

There are critical environmental considerations when handling tank by-products since they can damage the natural ecosystem if disposed improperly. There are many government and environmental regulations as well as green solutions that companies must abide by to minimize impact and save on natural resources.Depending on the size, and type of tank and waste needed to be collected, one of three main methods can be used for tank cleaning and include: man, and Automated Cleaning Technology (ACT) methods such as Clean In Place (CIP) or an advanced intelligent solution like the Magnetic Crawler Robot VertiDrive M7, in addition to 3D tools. Let’s take a further look into these options as we first explore why tank cleaning is so important for any industry that relies on them in their facility or site.

Tank Cleaning Basics: How does it Work?

Tanks are used to store various liquids and over time accumulate build-up that needs to be removed. As with all parts of a facility, tanks need regular monitoring and undergo inspections for lifecycle, repair and testing. One important aspect is corrosion, to make sure that structural elements aren’t deteriorating and causing the tank to become defective. Tank cleaning requires monitoring the levels of by-products and following a schedule for tank cleaning. In the long-run, this will make your tank structure last longer and work harder for you day to day. Who doesn’t want that in their facility? It’s a sense of confidence and peace of mind, but it requires due diligence.

It’s wise to plan ahead and have a contingency plan should you run into issues with your tank. Scheduled tank cleaning is a preventative measure every facility owner should consider and will pay forward with many years of use.

How Do I Go Above Regular Tank Cleaning Maintenance?

Consider an industrial cleaning company such as TEAM Group to take care of your regular tank cleaning needs, and more. Emergencies can happen, so having TEAM by your side will help you deal with facility or heavy industrial equipment malfunctions, breakdowns, and other major disruptions – tank related or not.

Services offered include scheduled and seasonal deep cleaning services for tanks related to byproducts of automotive, aerospace, pharmaceutical, food grade, and more. Others include shutdown services such as for Christmas Holidays, to save you time and money from maintenance during slower times of the year if applicable. Whether it’s regular maintenance to keep your facility running, or when it’s time to go back to the drawing board, TEAM is there for you to meet the challenge and offer you the best expertise in the industry.

Tank cleaning services are related to OEM & Tier 1/Fortune 500 integrated facilities management and are part of TEAM Groups trusted services. Don’t you think that’s something worth getting involved in?

When Should I Seek Tank Cleaning Services?

Tank cleaning is applicable for tanks of all sizes, those inside buildings as well as local municipalities and remote locations. If your facility depends on a tank, you need a tank cleaning service schedule.

- When an internal tank inspection is due, it will require cleaning and preparation (meaning emptying) so that a human technician can enter (called man-entry) or a robot sent in (non-entry). Once your tank requires this service is when you should seek the expertise of a technical industrial cleaning company such as TEAM Group.

- When your tank changes use (by storing a different product) is another moment when a tank cleaning service is required. The residue will need to be completely removed if you have plans to switch what will be kept inside the tank. Otherwise, debris and chemicals will build up and affect or deteriorate the new contents. An example is changing the contents from an unrefined product (such as crude oil) to refined (such as gasoline).

- When your tank is giving you mechanical issues, you may need to empty it and clean it depending on the situation. This could be a lengthy process, but is necessary for repairs to happen effectively. This will ensure a safe environment for the technicians entering for an inspection and repair job.

A Deep Clean: More Specifics on Tank Cleaning

Tank cleaning refers to a diverse number of services used to remove debris and sludge from industrial tanks. Each tank is different in terms of contents, volumes and access and as such, requires a specific approach for proper cleaning and maintenance.

The type of cleaning will be based on these aspects and will dictate what action is taken or not taken. For example, one tank can be entered by technicians (entry) while another isn’t (non-entry) and will require manless entry with a robot or the use of heavy duty cleaning equipment and various robotic tool extensions. When you partner with a company such as TEAM Group, we’ll provide you with the most experienced technicians who have the knowledge to carry out a custom solution for virtually any tank. We like a challenge.

Techniques and Tank Cleaning Methods

Let’s explore some of the techniques related to tank cleaning that may be applicable to your facility. Your specific job could require any combination of the below processes.

- Dredging and Dewatering Services: Requires the use of manned as well as remote-operated pumps and dredges. This is used for outdoor pits, containers or ponds such as ash pond sites or stormwater management.

- Water Jetting and Flushing: Requires machines that use high-pressure water streams to clean water and sewer systems such as road culverts, underground sewer lines, septic tanks, vaults, interceptor pits, and lift stations. Trucks then haul these away to appropriate disposal sites.

- Automated Line Leaning/Pipe/Tube Lancing: Single or multiple automated lance options are available for tank cleaning. Lance systems are automated tubes that drive the lance forward and pull it back under pressure, providing a thorough clean within the tube. Can be done either by a water blaster or a multifunctional automated robotic cleaning machine such as automated/mini excavator. This is a good addition for tubes that lead to and from tank systems. This system is a great option that could eliminate the need of using cranes and multiple technicians scaling a tank.

- Confined Space Entry (also called Man Entry): Requires the expertise of certified technicians who enter tanks such as silos, manholes or lift stations. Once inside, the technician completes required monitoring such as for ventilation, air quality, chemical control etc.

- Robotic Cleaning Technology: Where a human crew cannot enter, robots that are designed to pump out and also clean surfaces can enter the tank and in some cases can replace a human crew altogether. The use of robots may replace man entry, which significantly reduces the risk of on the job injury or mishaps. The use of robot cleaning technology may also be more effective in collecting all the required sludge in a safe manner therefore reducing the chance that some material is left behind due to human error. The technology here is advancing quickly, with robots being designed to effectively clean curved and irregularly shaped surfaces. Narrow, slippery and tricky places to reach such as those on large steel structures are no problem for some of these multi-purpose cleaning robots that are coming onto the market today.

- Tube Bundle/Heat Exchanger/Condenser Cleaning: This is an important piece of machinery to maintain, as the tubes that make up tubular heat exchangers are the most likely to corrode and are also the most expensive to replace. There are a number of techniques that clean condensers from stainless steel brushes, nylon brushes, and plastic scrubbers that are specifically designed for the tube size .

- Utility Manhole and Vault: Entering manholes and utility vaults is necessary for sludge and debris removal, whether it’s by a technician using a power washer or a robot entering to complete the job. You can work with TEAM Group to help set up the safest and more efficient inspections where you need them.

- Leak Detection and Repair (LDAR): Skilled technicians will first detect and then fix leaks in gas and oil pipelines, tanks and other equipment. LDAR is a collection of programs or methods used by trained professionals to monitor and identify equipment malfunctions that if left untreated, could cause further equipment decline.

Main Tank Cleaning Technologies

Tank cleaning technology varies just as much as the industries they serve. There is a solution and fit for any type of tank maintenance you require.

Tank Cleaning Machines (TCMs): Specific machines exist that are built so that their position and handy-work is optimized for even the tightest (or highest reaching) space. These can come in the form of powerful water jet capabilities. Using tank cleaning machines instead of manpower can help reduce the chemical, physical, fire, explosive, toxic and oxygen-limited environments that can be present in some tanks.

Advanced Tank Cleaning Machines: There is a range of services available, with some more technically advanced options. TEAM Group owns the only VertiDrive M7 in Canada, an example of an exemplary tank cleaning robot. It is designed to reach curved and irregular steel surfaces without losing grip. This is just one example of the TEAM Group difference – we always strive to bring the best technology to our clients.

3D Nozzle Tools: This includes a range of tools that can be rotating or fixed, and used for various applications. Typically the nozzle rotates due to the force of high-pressure water, which provides a superior clean when compared to traditional clean washing methods.

Cleaning in Place (CIP) Unit: A system that cleans interior product contact spaces such as pipes, without disassembling the process. This has great applications for interior pipes such as those used for food and beverage processing, mixers, blenders, and roasters. CIP systems are quick and efficient since they are typically built-in. CIP can reduce the chances of human error, since their internal monitoring sensors ensure to not miss any intended surface area.

Cleaning out of Place (COP): A system that relying on disassembly of equipment before cleaning. When parts of equipment cannot be safely cleaned on site, or need special access to hard-to-reach spots, then this is the method required. At times the equipment needs to be disassembled, moved to a specific facility or treated with special sanitization as required by the cleaning schedule. The requirement for disassembly requires trained professionals to ensure human error is avoided and that all surfaces are properly cleaned before reassembly.

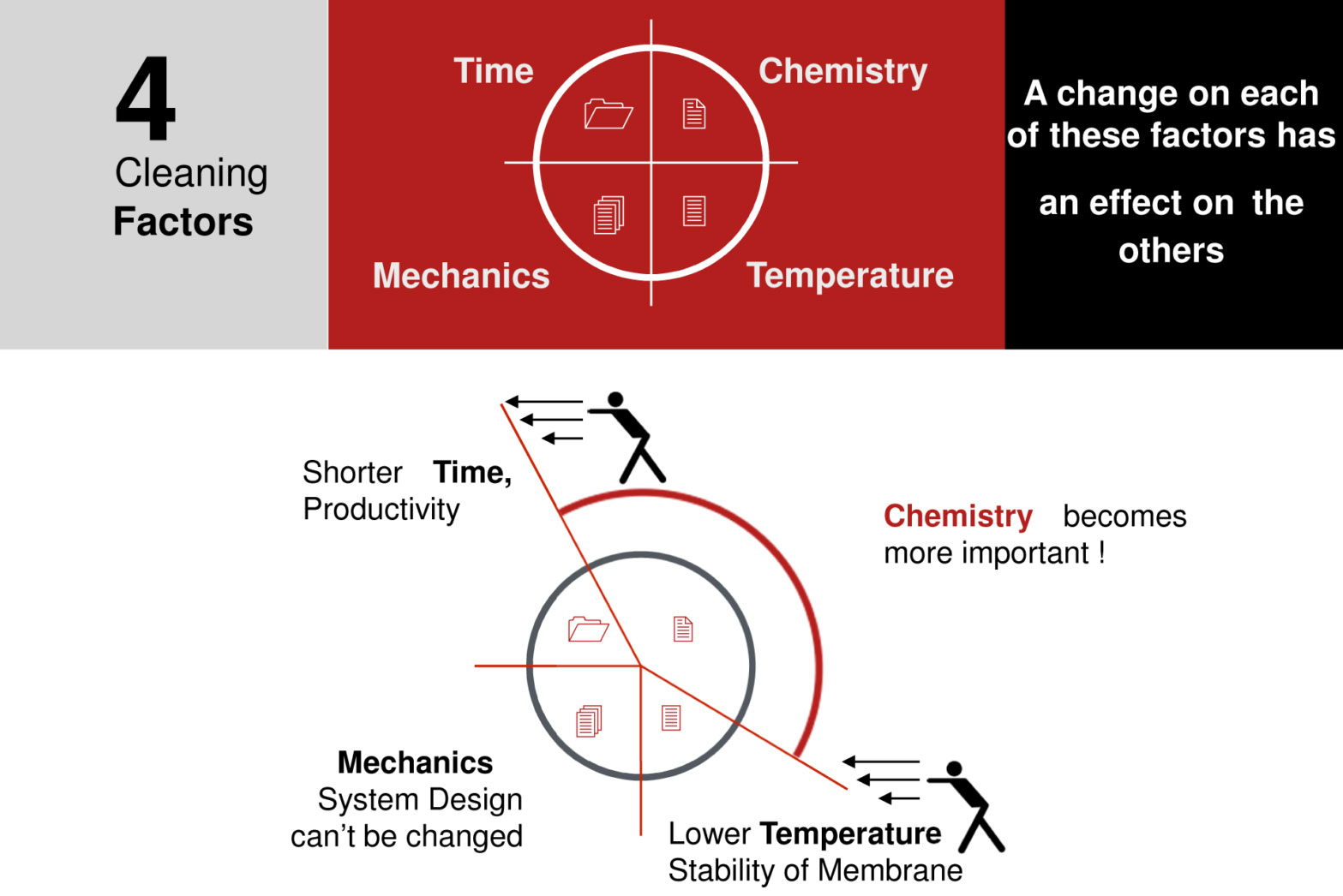

TACT Cleaning: Whether CIP cleaning or COP is taking place, the goal is to achieve a sanitary clean. To do so, the basic cleaning principles of TACT: Time, Action, Chemical and Temperature must be abided by. These cleaning principles were introduced in 1959 by Chemical Engineer Herbert Sinner. He wrote an educational book regarding automated washing machines that targeted housewives. He posited the four cleaning factors, Time, Action, Chemical and Temperature, define the result of the cleaning process. These processes are still adapted and hold true to any new technologies that appear on the market today. (These factors are represented in Sinner’s Circle, see Figure 1.)

Tank cleaning services do not have to seem complicated, or daunting. It comes down to confidence and experience, and that is what the technicians at TEAM Group can offer your facility. Experience the best technologies and highest safety standard with TEAM for all your tank cleaning needs.

ADDITIONAL RESOURCES

https://www.team-group.com/services/tank-cleaning-services/

https://team-group.com/facilities-management/automated-industrial-robot-cleaning/

https://team-group.com/commercial-cleaning/

https://team-group.com/commercial-cleaning/deep-cleaning-services/

https://team-group.com/automotive-paint-booth-cleaning/

https://team-group.com/commercial-cleaning/ultrasonic-cleaning-services/

https://team-group.com/services/industrial-vacuum-services/

https://www.vertidrive.com/products/m7-series/

https://www.nlbcorp.com/applications/tank-tote-cleaning/

https://www.stoneagetools.com/waterblast-tools-automated-equipment#tank